Hill International Wheel Alignment

Facts about a proven way to reduce tire costs

Millions of dollars have been spent on streamlining, improved drive trains and energy-efficient engines. Yet, most operators neglect one of the most effective ways to reduce operating costs… TotaI Wheel Alignment

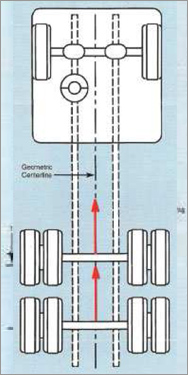

Our Total Wheel Alignment Service Minimizes Rolling Resistance, A Major Factor in Tire Wear

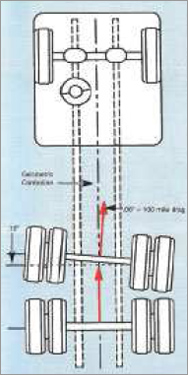

It’s estimated that over 70% of the trucks on the road have tandem axles that are misaligned in this way. To keep the truck going straight, the turning force of the tandem must be offset by turning the front wheels in the opposite direction. This causes all ten wheels to scrub …mile after mile.

Here’s what we do to help you cut costs….

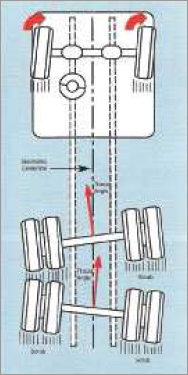

- We use electronic sensors to measure individual toe on one drive axle and determine thrust line.

- We align that axle to point down the center of the frame.

- We measure and align each of the other axles parallel to the reference axle, so all wheels roll in the same direction.

Our computerized alignment system does more:

Electronically compensates each sensor for runout — common because of bent or distorted rims.

References toe to centerline on the frame rails, so it correctly computes the thrustline, even when offset is present.

Because our system measures where the axles point, it isn’t fooled by setback.

Fact: It takes just a tenth of an inch to have a big impact on your cost!!

For example, what would happen if this rig has toe misalignment on the drive axle of only .10″ (or .06 degrees offset)?

If the mileage is 125,000 miles a year, the resulting effect is the equivalent of dragging the tires sideways for 100 miles!

Aligning the steer axle isn’t enough. One of the two most critical factors in front-end tire wear is drive axle misalignment. And a misaligned drive affects all the wheels on the rig.

Think of the impact on tire wear and fuel consumption and then multiply that by the number of tractors and trailers in your fleet

Here’s What Total Wheel Alignment Can Do For You:

Reduced Tire Wear

Improper alignment is a major cause of premature tire wear on all axles. Total alignment sets all wheels parallel. This can add thousands of miles to tire life.

Reduced Component Wear

When all wheels work with the system, stress on steering and suspension components is reduced.

Spot Problems Early

An under-vehicle inspection is part of our alignment procedure. This allows us to spot worn parts before they can cause costly problems.

Improved Handling

Proper alignment is necessary for optimum handling characteristics-contributing to increased safety and reduced driver fatigue, especially on ice and snow.

Minimize Rolling Resistance

Total alignment sets all wheels parallel. This works with proper inflation to minimize rolling resistance and improve operating efficiency, which helps reduce fuel consumption.